HyperCore has already been exercised in implementations on scales spanning three orders of magnitude difference.

- WCS Appliance Control: standalone but self-contained MHE piece-to-tote sortation device

- Non-Manifesting Micro-Fulfillment: in-store fulfillment

- Distribution Center: regional vendor in to store-out with some decanting and repacking as well as price-ticket inclusion or attachments

- BTC Fulfillment Center: inventory comes in through haulage freight, orders come in through whatever, and packages go out through consumer channel delivery carriers

Zone Groups are major functional areas (and sub-areas) in a warehouse. Zones are operationally functional sets of locations. And locations are where inventory can be stored or processed. The numbers of each of these progress steadily (especially for locations) from the appliance to the fulfillment center scales. These first three data columns in the table below represent the topological size of the implementations.

| Zone Groups | Zones | Locations | Strategy Types | Strategies | |

|---|---|---|---|---|---|

| WCS Appliance | 3 | 31 | ~200 | – | – |

| Micro-Fulfillment | 32 | 200 | 4100 | 6 | 18 |

| Distribution Center | 100 | 400 | 34000 | 5 | 120 |

| Fulfillment Center | 700 | 9100 | 400000 | 8 | 200 |

Strategies are the actual flow paths for each particular consumer and provider that has some way of transiting inventory between them to realize a particular strategy type.

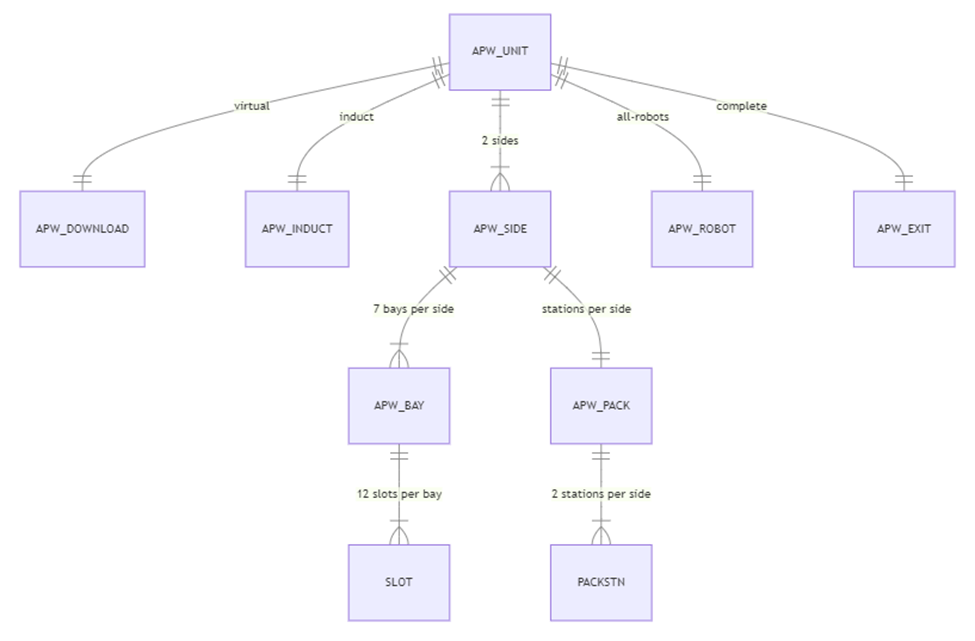

WCS Appliance Control

The singular WCS/MHE appliance referenced is an automated put-wall unit (zone-group) with 2 sides (also zone groups), each with 7 bays (zones) of slots, and 12 put-wall slots (locations) per bay. Within the model for this solution, additional locations, zones and zone groups cover the entirety of the device solution operations for inventory dropped off through to packages completed. Included in these are internal device robot locations where pieces of inventory can be found, operational locations such as scanners, and virtual locations based on messages from the host system.

As an appliance outside a fully StockFlow enabled warehouse, there are no strategy types defined. What is delivered and expected to be packed are pre-decided by the host system and actualized by human pickers with carts walking pick-paths.

What the appliance is responsible for is sorting pieces inducted from each cart into a tote in the wall assigned for an order, if there are no assigned orders matching the piece, but there are unassigned totes and potential orders, the system assigns the tote to the most “pressing” order (based on prioritization rules and what the cart was intended to be picked for).

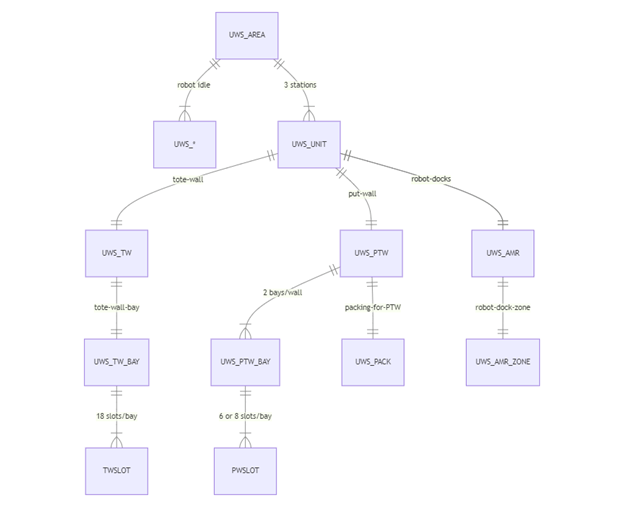

Micro-Fulfillment

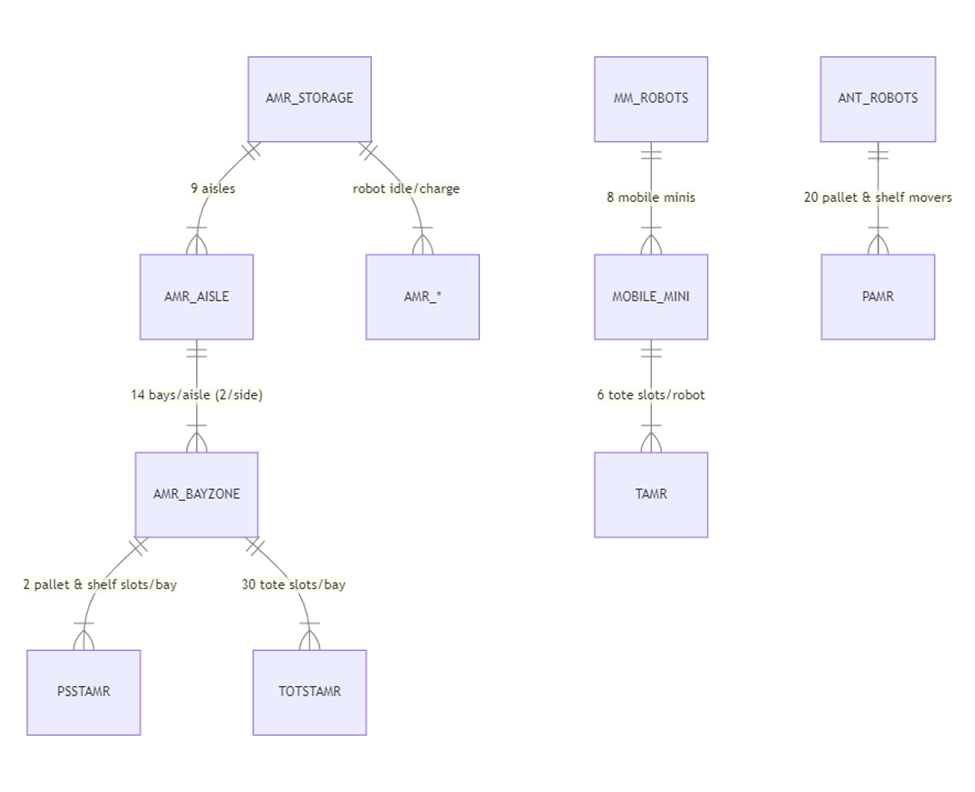

The micro-fulfillment implementation presented here uses two types of robots (multi-tote movers, and pallet/shelf movers) to move containers of inventory between a shared storage space of racking and floor locations, and processing units for replenishing that storage and fulfilling orders.

The implementation handles inventory storage and functional flows to and from the storage area, so the need for the 6 strategy types occurs, and with 3 processing stations zone groups that can handle any of the strategies and only one (overarching) storage zone group, that leads to 18 strategies in the solution.

The strategy types are:

- PUTAWAY: from a station to storage when done at station

- FULFILL: from storage to a station to pick for slotted orders

- REPLEN: from storage to station to add inventory

- PURGE: from storage to station to remove inventory

- COUNT: from storage to station to perform count operation on container contents

- EXCEPTION: from storage to station to inspect and correct container contents

The topology gets more complex (and larger). Now there is storage to track and model, in addition to a more complicated breakdown of transit and slotting at the processing stations (instead of a one-way flow in an appliance).

The storage and robot areas are also accounted for in this next graph. In actuality, the zonal topology contains all of these in a singular “warehouse” model, which is omitted from both graphs. The storage area’s size can be roughly seen by multiplying the aisles by the bays by the slots (9 * 14 * 32) = ~4032. Though the number of container compartments is higher when multi-shelf stands are taken into account.

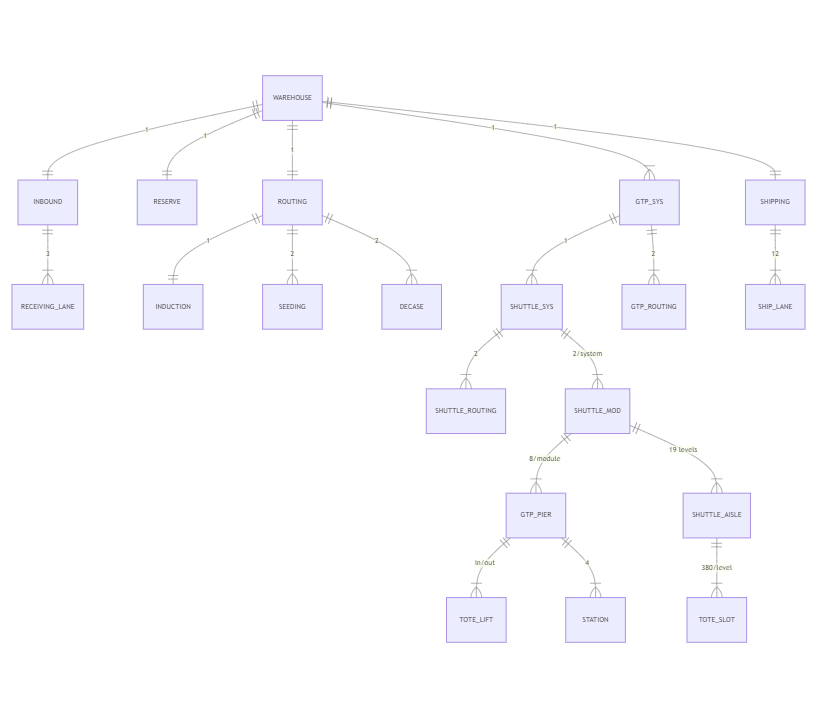

Distribution Center

The distribution center implementation is an order of magnitude larger than the micro-fulfillment center, largely due to the shuttle storage system used as an intermediate buffer for case decanted inventory intended to be repacked for shipments to retail stores – in a good-to-person (GTP) functional model. This system also uses diverting conveyors to move received cases from inbound lanes to shipping lanes with intermediate processing and decisioning.

This next diagram makes more generalizations at the lower end (for instance singular container processing stations at seeding and decase are omitted), but should still keep the sense that the topology of the solution gets more connected and involved as the scale of the implementation increases.

In addition to the GTP processing the routing system may divert whole cases received directly to shipping as demanded by the host system; potentially stopping for intermediate seeding of tickets and ticket attachment to merchandise as needed by store and item requirements.

The number of strategy types is small (mostly fulfillment pulls, return to storage and push between stations), but the number of strategies is large reflecting the large number of stations that can pull inventory and return from storage.

Fulfillment Center

The fulfillment center profile presented here represents another order of magnitude in location capacity above the distribution center illustrated before, and represents the largest HyperCore profile implemented to date.

It uses a large – in comparison to the micro-fulfillment profile – robot accessible storage on two distinct levels (with dozens of robots servicing them), multiple automated put-walls, multiple singles packing stations (for each of bag and box shipment containerization), multiple manual order put-wall stations, multiple bag and box packing stations for multi-item orders coming either put-wall type (automated or manual), non-conveyable storage and non-conveyable packing areas, bulk storage, print and apply, and shipping.

Additionally, conveyors and diverts move totes from receiving into storage for robot pick-up and put-away, and from packing areas to print and apply and shipping, in addition to conveyor moving totes from robot drop-off and pick-up locations near APWs and singles packing stations.

The top-level zone group types:

- AMR_PROC: robot accessible storage (1 per floor, 2 floors)

- APW_PROC: automated put-wall (3 per floor, 2 floors)

- BULK_STORAGE: 1 per facility, on ground floor

- INBOUND: 1 per facility, on ground floor

- LOST: inventory detected as lost moved here for reconciliation

- NONCONVEY_STORAGE: items too big to fit into totes

- NONCONVEY_PACK: packing for items too big, singles orders

- PACKING: packing after assemblage into containers (includes singles packing)

- ROBOTS: per floor, where tote-carrying robots are found

- SHIPPING: 1 per facility

- TRANSIT: movement of inventory via manual intervention in NONCONVEY and BULK

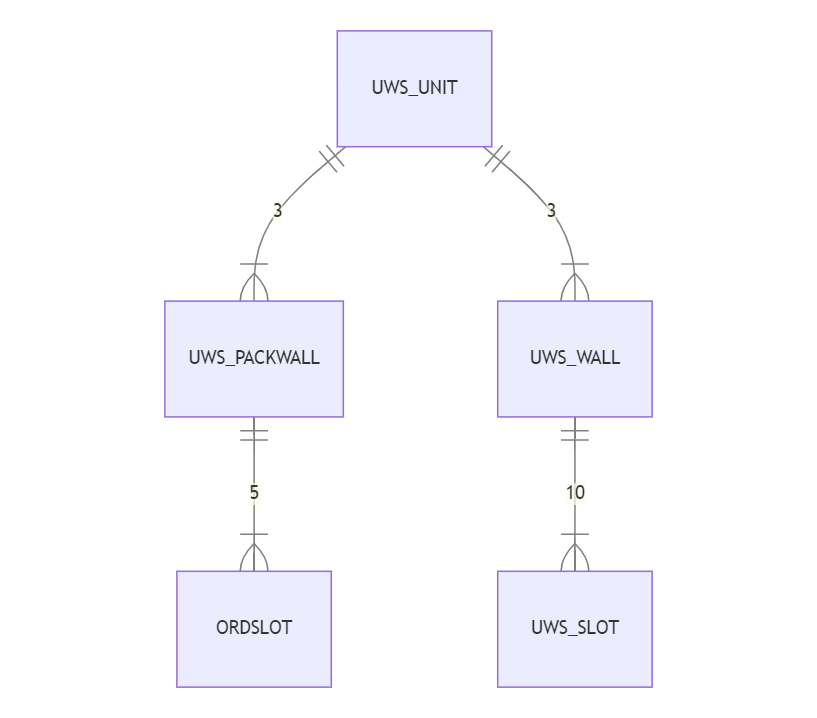

- UWS_UNIT: processing of non automatable items and other inventory control operations, 8 per floor

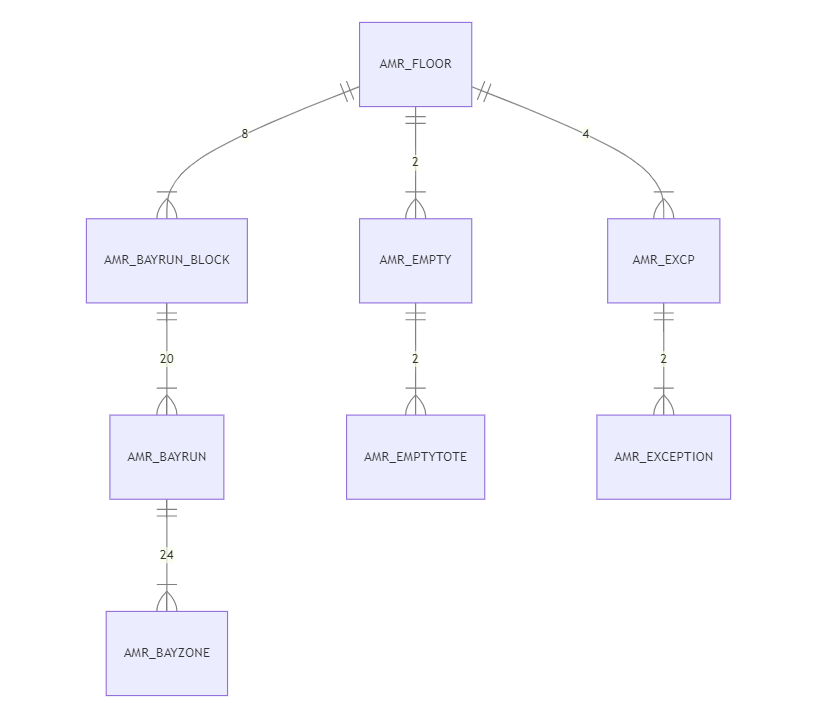

First, details on the AMRs (minus the number of slots per bay, which is 50). Multiplying 2 floors by 8 blocks by 20 “bay runs” by 24 bays by 50 slots = 2*8*20*24*50 = 384000 tote storage locations.

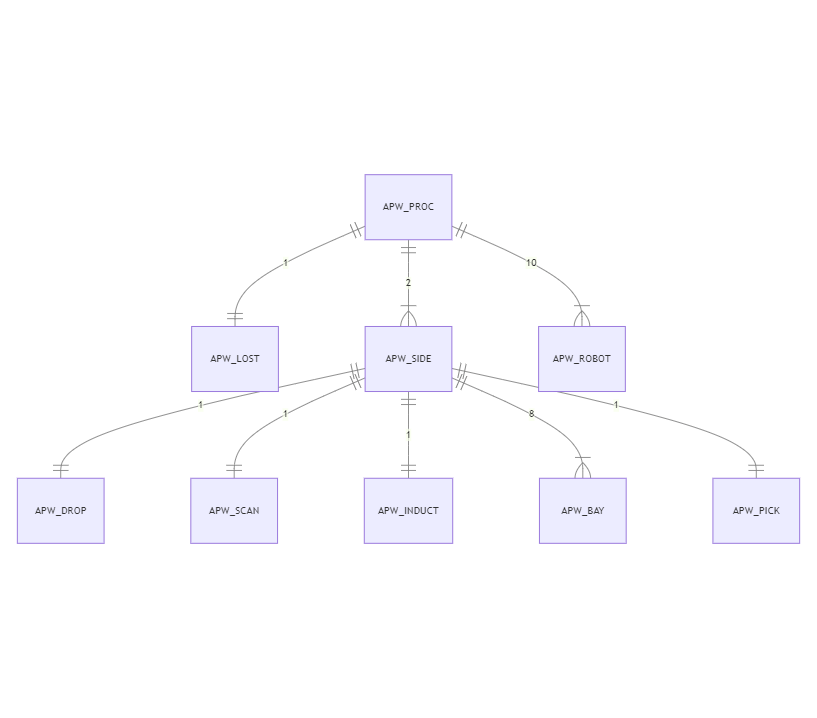

Next, the APWs (simplified somewhat from the single appliance) with each bay holding 16 slots (or assignable orders) gives 256 per APW, or 6*256 = 1536 orders slotted at once for fulfillment.

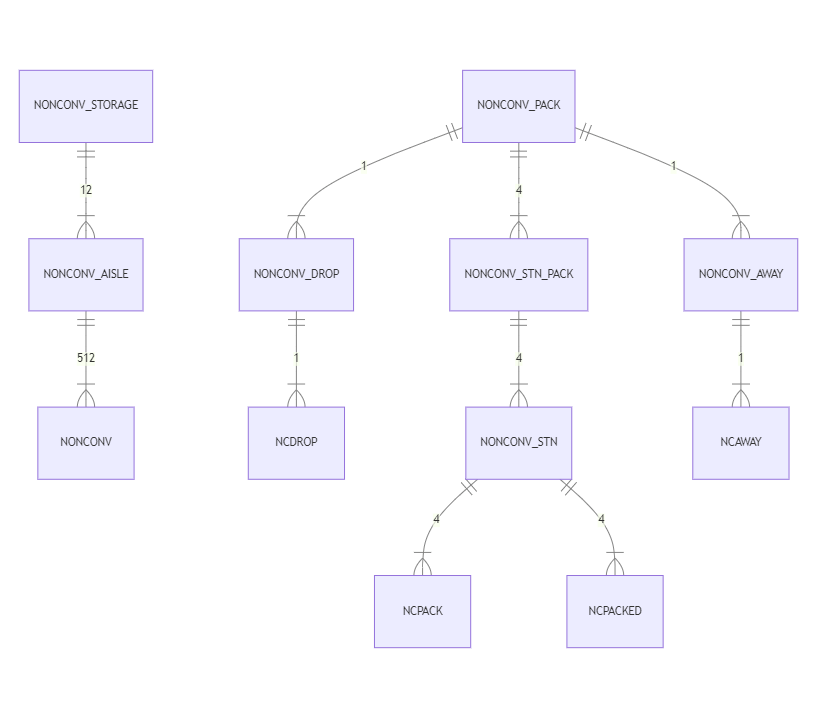

Both ends of the non-conveyable strategies. Non-conveyable storage locations hold pallets of what are effectively singleton cases. Picking from them is accomplished by directed moves of a user with a pallet on a pallet jack (or some such capable transporter) to load a number of cases from storage to the transit pallet for delivery to the packing area. StockFlow recognizes the need to the fulfillment strategy to use this type of picking and allocation between the consumer and provider.

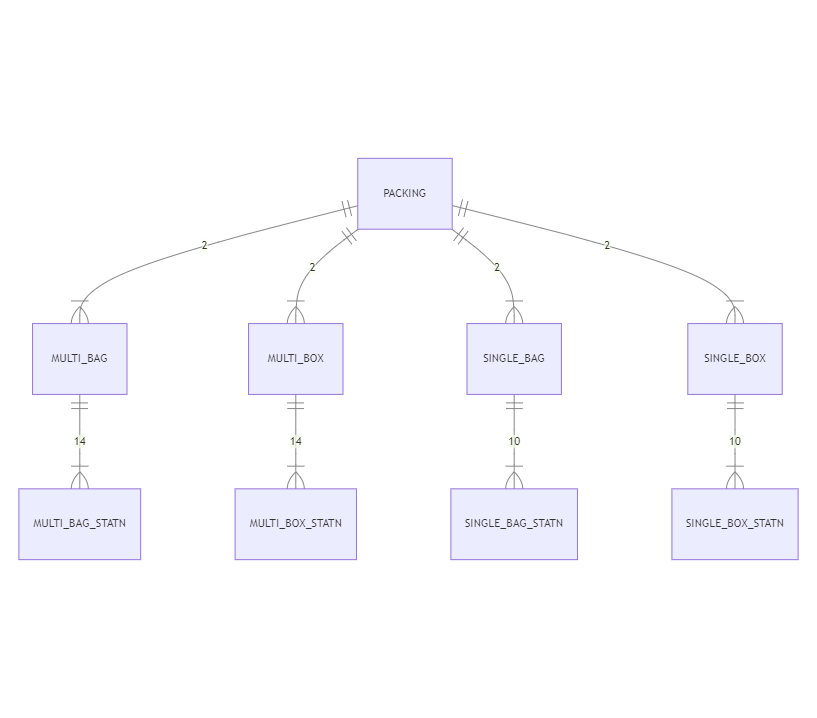

Packing (simplified) includes both the singles packing where storage totes are delivered for bag or box, and the multis packing where order sorted totes from the APW or manual stations are sent via conveyor for packing.

The workstations presented here have been simplified (in presentation) but are similar to the workstations used in the micro-fulfillment. There are just more of them.

There are unique strategy types for poolable orders (singles), and wall consolidation orders (multis), specific strategy instances between the nonconveyable storage and nonconveyable packing, and alternative singles packing strategies that can be enabled for bypassing robot picking and delivering pallets to singles stations for hot-throughput singles packing.

In addition, full inventory control of storage and a few exception flows round out the larger number of strategies and strategy types.

Mostly the larger number of strategies is due to the larger number of processing locations that can consume inventory, and the 3 distinct areas that can provide (2 floors of robot and 1 non-conveyable).