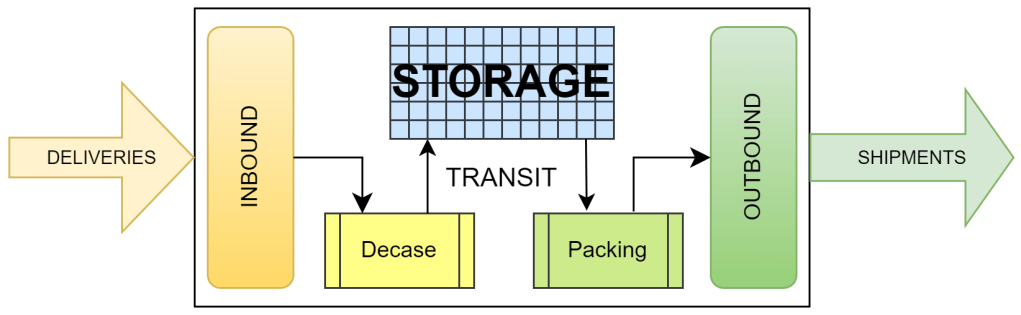

Inbound or Receiving

Inbound can be considered as a sub-system with its boundaries partitioned by its location within the larger within proximity of the receiving docks. While functioning, inventory is moved from the off-loading vehicles into the broader inbound area for future processing when validated. Future processing is handled by the other sub-system areas in the warehouse, such as Storage Preparation and Transit Systems processing movements away from the inbound area.

The inbound area of a warehouse itself may have any of the following:

- Inbound dock doors

- Receiving conveyors

- Staging locations for put-away or cross-dock operations

Storage Preparation

Storage preparation involves a number of components (many of which are optional)

- Confirming inventory received

- Decanting pallets to cases (labeling and associating as needed)

- Decanting inventory in cases to totes (labeling and associating as needed)

- Recombining into other pallets

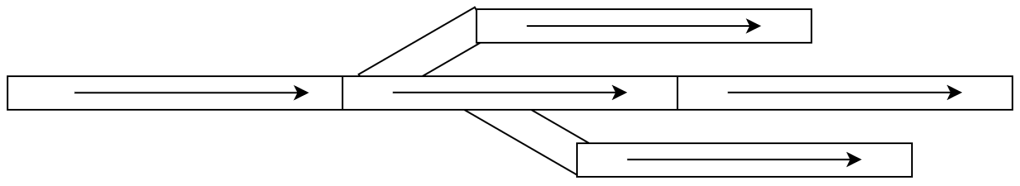

Transit Systems

In transit systems, the source and destination are the inbound and outbound of the transit system. Each discrete leg of a transit system can be a “system in itself” and the entire transit network can also be seen as a system. In a warehouse, multi-modal transit routes are possible and the transit network from source to destination is a system.

- Conveyors for cases and totes (with lanes and diverts)

- Pallet movers (jacks and fork-trucks)

- Pallet conveyors

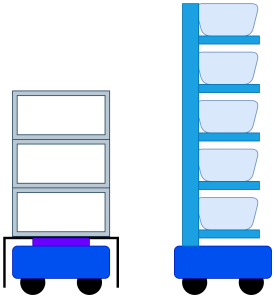

- Tote transporting robots

- Pallet transporting robots

- Gantry cranes

- Shuttles and Lifts

- Human-driven push carts

Various types of robots can be used for automated container transit.

Some robots can move pallets and shelfs, others can move multiple totes.

Storage

There are a variety of forms of storage, often based upon the type of container and transit systems that can access the storage locations. Also, the expected time-horizon for use can greatly influence the nature and structure of storage accessibility and form. Some examples of storage locations are given below:

- Reserve Areas: usually containers of inventory that will feed some other storage system where accessibility is more favorable for use; inventory is held in reserve when the more accessible locations are more valuably occupied with inventory more urgently needed

- Bulk Item Areas: inventory that is too large to fit into other storage locations; typically requires own picking operations to gather inventory for outbound

- Human Accessible Racking: usually totes or open cases that are at human accessible heights; inventory often gathered into totes to fulfill an order, to fulfill a set of single item orders, or to feed a unit sorting device to distribute to multiple orders

- Roaming Robot Accessible Racking: usually totes stored at height that may exceed human height accessibility limits and thereby increase floor storage density by going vertical beyond human capacity, roaming robots need exclusive areas to avoid contact with humans, but need less extensively installed infrastructure than shuttle robots

- Shuttle Robot Accessible Racking: usually totes stored in an enclosed racking system that are only accessible by a shuttle robot operating on rails, often paired with lift systems to increase vertical density; shuttle systems have dedicated transit hardware (i.e., rails), with increased pick speed and vertical density higher than most roaming robots typically achieve. They also get power from the rails so have a longer service cycle time than roaming robots

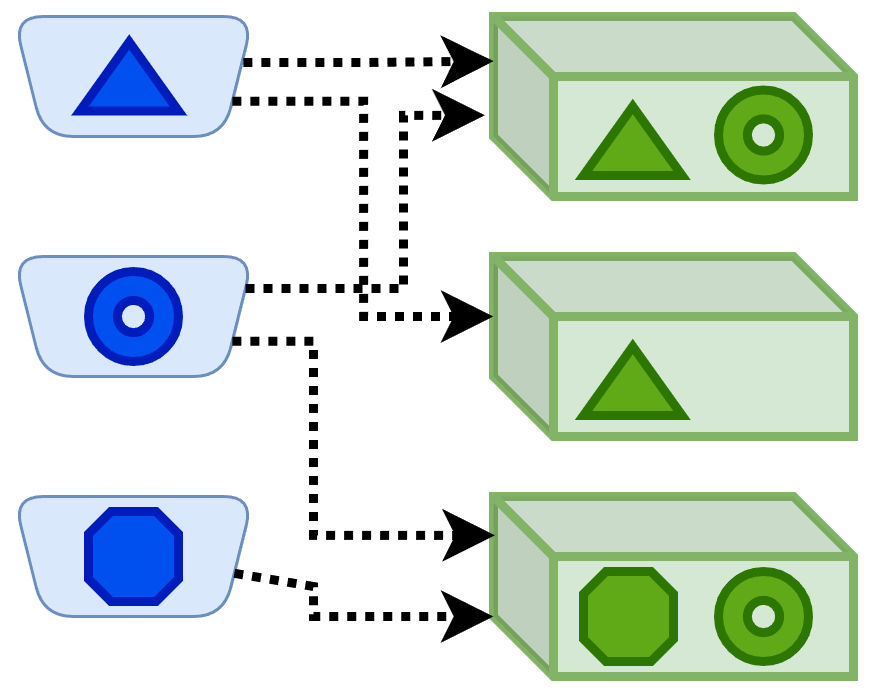

Outbound Preparation

Outbound packages or shipments may be subsets of inbound or stored inventory, or combinations or inventory from multiple source containers. Outbound preparation as order fulfillment is meant for “customer-centric” orders. Outbound preparation for distribution to channel partners and stores (or other distribution centers), may involve moving pieces between containers, or containers onto larger pallets for shipment.

In either situation there is (usually) the aggregation or division of inventory from storage or received case containers into outbound containers. The outbound containers need to be tagged with routing identifiers (carrier manifest labels or other shipment information) that is synchronized with external logistical systems and represent information to the carrier or shipper for their logistical routing.

Pieces of inventory are moved from storage totes to outbound containers to fulfill order requirements or shipment allocations.

Outbound

The final sub-system is outbound itself, when outbound containers with various items are sorted to outbound truck lanes and eventually leave the warehouse as a system. Logically the inventory may leave when confirmed at a lane, or when the trailer door is confirmed closed by transaction or system integration message.